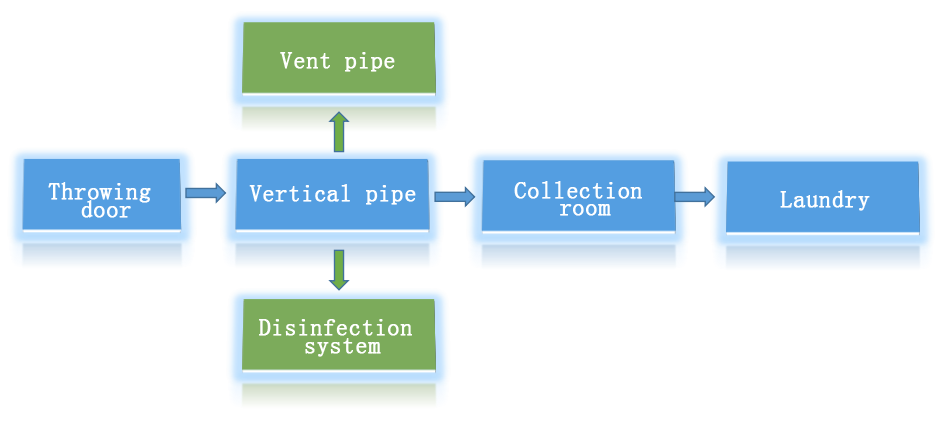

The quilt pipeline collection system consists of pipeline system and electronic control system.

I. Pipeline System

The whole system consists of main pipe, exhaust pipe, discharge port, discharge port, inspection port, horizontal conversion equipment, disinfection equipment and so on.

II. Electronic Control System

The electronic control system adopts modular system based on operation safety requirements. The system has the functions of general control, interlocking, status display and fire fighting linkage, and the functions can be expanded.

The master control box is installed in the bedclothes collection room. Touch LCD operation screen is used to display the system usage status, and system switch keys, interlock keys, pipe disinfection, door suction control keys are set.

When the staff collect the bedclothes centrally, they can close the discharge door manually to prevent the staff from being injured when the bedclothes slip out.

Interlocking function: Only one drop door can be used at a time, that is, one drop door can be opened, the other floor drop door can not be opened.

Fire Link Function: The main control box should be linked with the fire control center. When there is an alarm, the system will automatically close. At the same time, the fire valve will be closed, the discharge door will be closed automatically. The unlocked release door will be locked. If there is an unlocked release door, the alarm prompt will be given.

The key electric latch is used to put the door on, and the latch is unlocked when the power is on, which meets the requirement of energy saving. Show the current status of the system with a light above the opening door. You can swipe the card to open the door.

Fire valve: connected with fire control center, equipped with 70 degree fuse wire, manual reset.

|

|

| Discharge door | Control box |

|

|

| Throwing door | Control screen |